Since 1992 VIVACO company has been into development and manufacturing of plants for continuous production of water, water-enzyme and water-alcohol extracts from plants (dry cut herbs, flowers, roots, bark, etc.) using vertical screw extractor (RF Patent No.2131757 dd. 20.06.99). Since 1992 VIVACO company has been into development and manufacturing of plants for continuous production of water, water-enzyme and water-alcohol extracts from plants (dry cut herbs, flowers, roots, bark, etc.) using vertical screw extractor (RF Patent No.2131757 dd. 20.06.99).

Extraction plant operates on the continuous countercurrent extraction principle (based on effective diffusion process) and includes the following main units: Extraction plant operates on the continuous countercurrent extraction principle (based on effective diffusion process) and includes the following main units:

- extraction unit - two vertical columns, containing perforated screw conveyers, which bring the raw material upwards countercurrent to the extractive agent poured from the above, one variable motor with torque transmission system. Extraction column design ensures guaranteed uplift of vegetable material and controls its speed by means of movable self-cleaning column cover. Monitoring, cleaning and washing of the conveyers is performed through the inspection manholes all along the column height; - extraction unit - two vertical columns, containing perforated screw conveyers, which bring the raw material upwards countercurrent to the extractive agent poured from the above, one variable motor with torque transmission system. Extraction column design ensures guaranteed uplift of vegetable material and controls its speed by means of movable self-cleaning column cover. Monitoring, cleaning and washing of the conveyers is performed through the inspection manholes all along the column height;

- extractive agent delivery system - two dosing pumps, one transfer pump, three auxiliary gauging vessels; - extractive agent delivery system - two dosing pumps, one transfer pump, three auxiliary gauging vessels;

- control and monitoring system - one control cabinet, one control desk. The plant is made of stainless steel, explosion proof. - control and monitoring system - one control cabinet, one control desk. The plant is made of stainless steel, explosion proof.

Research work and production tests shows that continuous vertical screw extractors out-perform all current extractors by many parameters. Research work and production tests shows that continuous vertical screw extractors out-perform all current extractors by many parameters.

|

|

|

The cost of plant (to be specified at ordering)

depending on the set content and the Customer's requirements:

|

| Designation |

Extraction,

litres/hour |

Weight,

kg |

Overall dimensions,

mm |

Cost,

USD |

| EBH 500 |

max. 0.5 |

44.0 |

400x300x1100 |

4750.0 |

| EBK-10 |

max. 15 |

600 |

2000x1500x2300 |

43050.0 |

| EBK-2 |

max. 150 |

4000 |

4100x3000x4400 |

57600.0 |

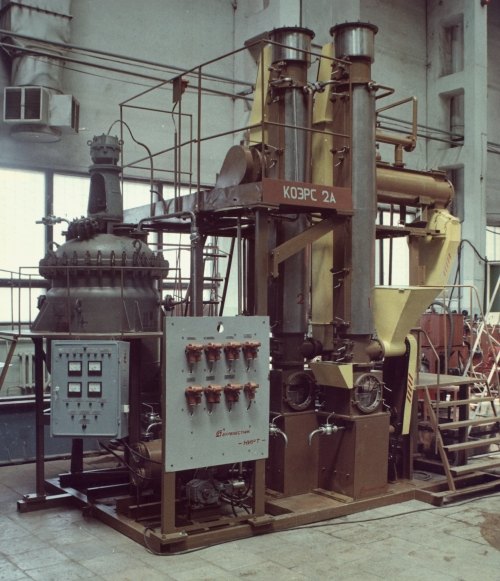

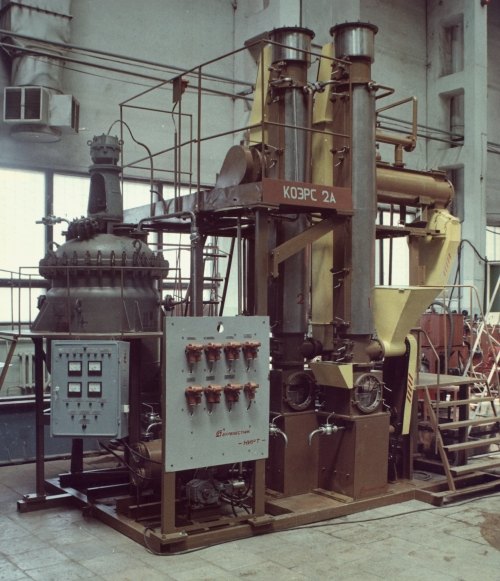

SEEVRM-2A

(KOERS-2A) |

max. 150 |

6000 |

4100x3000x4400 |

85500.0 |

|

Extract concentration,% - up to 15; Extract concentration,% - up to 15;

Extraction factor,% - up to 97; Extraction factor,% - up to 97;

Extraction time, hours - 4-9. Extraction time, hours - 4-9.

|

Depending on technological requirements and the Customer's manufacturing conditions the plants may be fitted with additional units: Depending on technological requirements and the Customer's manufacturing conditions the plants may be fitted with additional units:

- extractive agent preparation unit - steam-jacketed apparatus with mechanical mixer; - extractive agent preparation unit - steam-jacketed apparatus with mechanical mixer;

- column and extractive agent heating system with automatic temperature control device; - column and extractive agent heating system with automatic temperature control device;

- ground oil-cake regeneration alcohol system; - ground oil-cake regeneration alcohol system;

- ground oil-cake pressing unit. - ground oil-cake pressing unit.

At presents extractors of other types and designs are under development. If you are interested in detailed information please do not hesitate to contact us. At presents extractors of other types and designs are under development. If you are interested in detailed information please do not hesitate to contact us.

|

|

|

|

Set of equipment for vegetable raw material extraction KOERS-2A (SEEVRM-2A)

|

|

|

Products

produced by the vegetable material extraction plants and their use

|

Aiming at increased production of vegetable extracts - biologically active substances carriers - as one of the most important goals, VIVACO company has developed and put into production vegetable extraction machine complex by means of water, water-enzyme and water-alcohol extractive agents. Aiming at increased production of vegetable extracts - biologically active substances carriers - as one of the most important goals, VIVACO company has developed and put into production vegetable extraction machine complex by means of water, water-enzyme and water-alcohol extractive agents.

Using this equipment and changing the process it is possible to obtain the following extraction products: pharmaceuticals, flavoring and medical additives for infants' food, disease-preventing beverages (different for different professions), flavoring agents, antioxidants for food industry, preservatives, food color, tannin agents, perfumery and cosmetics, etc. Using this equipment and changing the process it is possible to obtain the following extraction products: pharmaceuticals, flavoring and medical additives for infants' food, disease-preventing beverages (different for different professions), flavoring agents, antioxidants for food industry, preservatives, food color, tannin agents, perfumery and cosmetics, etc.

Water-alcohol extracts from calamus root, oak bark, John's-wood, brotherwort, foalfoot and spearmint leaves, ashberries, etc. added as preservatives to oil, fat or water-fat emulsions in proportion 0.2-0.04% (200-400 mkg/kg) improve their quality, curative properties and increase storage time up to 90 days (i.e. making it thrice as long). Water-alcohol extracts from calamus root, oak bark, John's-wood, brotherwort, foalfoot and spearmint leaves, ashberries, etc. added as preservatives to oil, fat or water-fat emulsions in proportion 0.2-0.04% (200-400 mkg/kg) improve their quality, curative properties and increase storage time up to 90 days (i.e. making it thrice as long).

Water extract from nettle leaves added to dough increases mineral, protein, wet and dry gluten content - i.e. restores the properties lost at thrashing and thus improves bread quality and gives it curative properties. Water extract from nettle leaves added to dough increases mineral, protein, wet and dry gluten content - i.e. restores the properties lost at thrashing and thus improves bread quality and gives it curative properties.

Extracts from some plants may be used for producing preventive beverages with radioprotective properties. Extracts from some plants may be used for producing preventive beverages with radioprotective properties.

Alcohol free beverages based on such extracts contain biologically active substances - essential oils, phenolic substances with P-vitamin activity, vitamin C, mineral substances and amino acids. These beverages improve human organism resistance to radiation, stresses. The beverage life increases to more than 30 days due to the use of natural preservatives contained in vegetable material. Alcohol free beverages based on such extracts contain biologically active substances - essential oils, phenolic substances with P-vitamin activity, vitamin C, mineral substances and amino acids. These beverages improve human organism resistance to radiation, stresses. The beverage life increases to more than 30 days due to the use of natural preservatives contained in vegetable material.

In future prospects the extracts can be used in perfume industry - creams, shampoos, balsams with increased biological activity. In future prospects the extracts can be used in perfume industry - creams, shampoos, balsams with increased biological activity.

After certain modification the plant can be used to produce essential oils and flavored alcohol. After certain modification the plant can be used to produce essential oils and flavored alcohol.

|

|